Products

High Temperature Resistant Silicone Rubber Washer Gasket

High Temperature Resistant Silicone Rubber Washer Gasket

| Product name | High Temperature Resistant Silicone Rubber Washer Gasket |

| Material | 100% Pure, Professional Quality Food-Grade Silicone. Meets US FDA and European LFGB Safety Standards. |

| Brief Description | 1) Free sample for our stock samples, but the freight should be paid by customers.2) For customized sample, we would charge you a set-up fee. |

| Sample | Customized logo is welcome |

| Logo | Customized logo is welcome |

| Color | Any pantone color |

| Export Port | Shenzhen |

| Supply Ability | 50000 Pcs./ Days |

| Delivery Date | 15-20 Days |

| Trade Terma | EXW, FOB, CIF, DAP |

| Transportation | Air, Sea, FedEX, DHL, UPS, EMS |

| Payment Terms | T/T, WU, Paypal, Trade Assurance, L/C |

Material & Application

Often underappreciated but vital to thousands of machines and household appliances, rubber gaskets help make our everyday life possible. They seal our refrigerator doors to keep food fresh; they keep ammunition protected from moisture; they help build bridges. What is a rubber gasket and how is it used in all of these applications? Well, it is a mechanical seal that is used primarily to prevent leaks of gas or liquid, but can be used as a barrier between two objects, such as two metals or chemicals. They are often utilized as protection from outside elements as well. In a camera lens, they combat moisture and dust to ensure that the lens stays focused and speck free. Used in almost every industry, this fabricated rubber product is versatile and necessary for thousands of applications. There are rarely two applications that use the same shape or size gasket. Gaskets are made specific to each use and this makes this industry very unique!

Rubber Gasket are available in the following elastomers:

- Aflas® or Kalrez®(FFKM)

- Acrylate Rubber(ACM)

- Butyl Rubber(IIR)

- Ethylene-propylene (EPR, EPDM)

- Fluorocarbon (FKM/FPM/VITON)

- Fluorosilicone(FVMQ)

- Hydrogenated Nitrile (HNBR)

- Liquid Silicone Rubber(LSR)

- Neoprene Rubber(CR)

- Nitrile Rubber (Buna-N/NBR)

- Natural Rubber(NR)

- Polyurethane(PU)

- Silicone Rubber

- Styrene-butadiene Rubber (SBR)

Properties of Rubber Gasket Material:

ZICHEN Rubber fabricates superior custom rubber gaskets that can be die cut or CNC flash cut from a variety of rubber materials.

Rubber Gasket used in wide application of various fields, our rubber gaskets offer excellent resilience and sealing for applications involving low temperatures and pressures and mild chemical environments.

Our team of engineers can guide you through the process of selecting the ideal rubber material for your unique gasket applications:

l Butyl – A copolymer of isoprene of isobutylene, butyl is a synthetic rubber with several distinctive benefits. Butyl is impermeable to moisture and various gases, making it an ideal choice for airtight applications. With a service temperature range of -40°F to 225°F, this material has exceptional resistance to chemicals, abrasion, and diverse weather conditions. Butyl can easily adhere to other rubber materials, and it has great electrical insulation properties.

l EPDM – Ethylene propylene diene monomer, commonly known as EPDM, is an elastomer known for its high durability and versatility. EPDM has excellent resistance to heat, ozone, oxygen and oxygenated solvents, chemicals, animal and vegetable oils, and harsh weather. Stable in low and high temperatures, this material has a service range of -40°F to 250°F and is intermittent to 275°F. Additionally, EPDM can resist polar and steam substances with great proficiency.

l Natural (Pure Gum) – Natural rubber is a polymer consisting of isoprene. This soft material has high elasticity, which provides superior physical properties such as resistance to abrasion and low temperatures. Ideal for applications requiring acids, organic salts, and other chemicals, natural rubber is non-toxic and has a temperature range of -20°F to 170°F.

l Neoprene – Neoprene is a synthetic rubber created by polymerizing chloroprene material. Also called polychloroprene, neoprene is a flame-retardant material that can also resist the effects of oils, chemicals, oxygen, and ozone. For applications requiring higher tensile strength and ease of movement, cloth inserted neoprene is available; each variation can operate within the same -20°F to 170°F temperature range.

l Nitrile (NBR, Buna-N) – Nitrile is a copolymer of butadiene and acrylonitrile. This synthetic rubber material is resistant to various solvents, hydraulic fluids, animal and vegetable oils, and aromatic fuels; nitrile can also diminish the effects of heat aging. Nitrile performs optimally in temperatures ranging from -25°F to 170°F, and it is available in premium, commercial, and FDA grades.

l SBR – Styrene-butadiene rubber (SBR) has similar properties to natural rubber, but is more resistant to abrasion, wear, and hot and cold water. SBR has excellent adhesion to metals, and is available in red rubber and cloth inserted varieties; the latter is more proficient at handling movement, high compression loads, and saturated and low pressure steam. Each SBR variation can operate within the same -20°F to 170°F temperature range.

l Silicone – An extremely soft and adaptable material, silicone is composed of polymerized siloxanes. Silicone boasts superior elastomeric properties at both high and low temperatures and is resistant to the effects of ozone, oxygen, aging, ultraviolet (UV) light, and extreme weather conditions. Available in FDA grade, this material was a wide temperature service range of -67°F to 400°F and is intermittent to 450°F.

l Vinyl – Polyvinyl chloride (PVC) is a synthetic plastic polymer commonly used in applications with water or oxidizing agents. PVC material offers excellent resistance to abrasion and weather, and is available in rigid or flexible forms to suit various application needs. This material is ideal for temperatures ranging from 20°F to 160°F.

l Viton® – Known for its outstanding resistance to chemical substances, Viton® is a fluorocarbon-based synthetic rubber. This material can perform optimally in the most extreme conditions—Viton® has a maximum operating temperature from 400°F (continuous) to 500°F (intermittent). Additionally, this material can repel oxygen, ozone, various fuels and oils, solvents, and hydraulic fluids.

Most rubber, whether natural and synthetic, is also available in sponge form (cellular rubber) in both open and closed cell grades. Zichen Rubber offers neoprene, nitrile, silicone and Viton in sponge form. Closed cell sponge is available for applications requiring high compressibility, while open cell is available for cushioning applications where sealing is not an issue.

Using material sourced from domestic rubber manufacturers, ZICHEN keeps a large quantity of rubber materials in stock and can provide custom designs and shapes in varying grades, thicknesses and hardness to meet your specific needs.

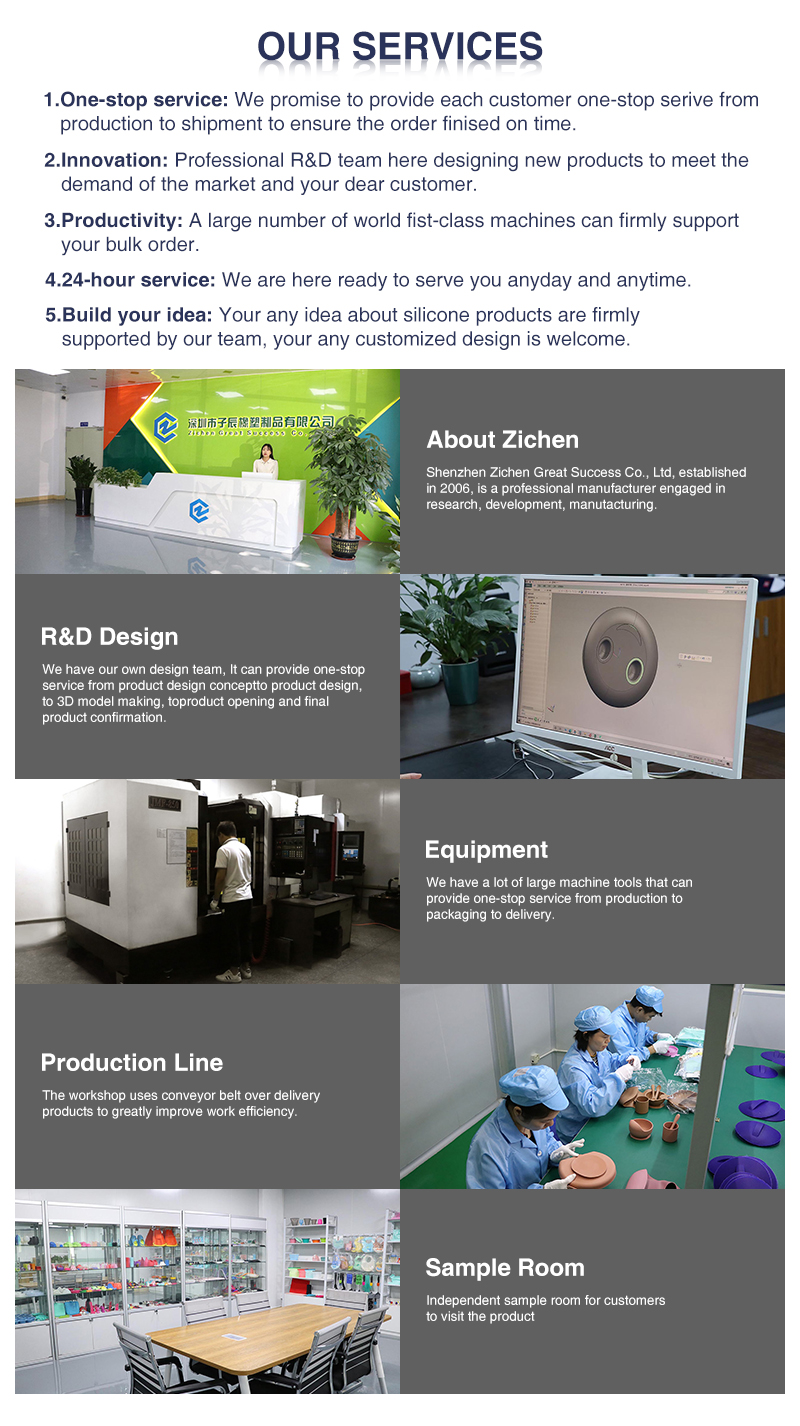

ZICHEN GREAT SUCCESS Co.Ltd locates in shenzhen city, Guangdong province. It was founded in 2002, has 6000 square meters of factory,registered capital 600 million RMB.

Main products: rubber,silicone and plastic products including daily life product,kitchenware, health care product,sex toy and children toy and custom parts applied in electric home appliance,automotive and spaceflight industries etc.. With the experience more than 10years, our products have been exported to USA, European, and Asia, Southeast Asia etc.

Our factory adheres to the “customer first, forge ahead” business philososphy, adhere to the “customer first” principle to provide our customers with quality service.our key goal is creating value deliver efficiency ,building your green life.Welcome to visit and cooperate with us!

Contact us for cheaper shipping

We provide custom services as below:

Excellent Service for E-commerce customers

Quick Shipping/Quality Assurance/Hot Sale/Nice Feedback

1. What is You Company Product Range?

chains. We provide one-stop service and welcome OEM and odm.

have received it. Each step of production and finished products will be carried out and inspection by QC before shipping.